Linha de máquina para fabricação de grânulos macios de PVC em flocos de PP

Visão geral Tamanho do pacote 500,00cm * 200,00cm * 200,00cm Peso bruto do pacote 2700,000kg Flocos PP Pvc Grânulos maci;

Overview

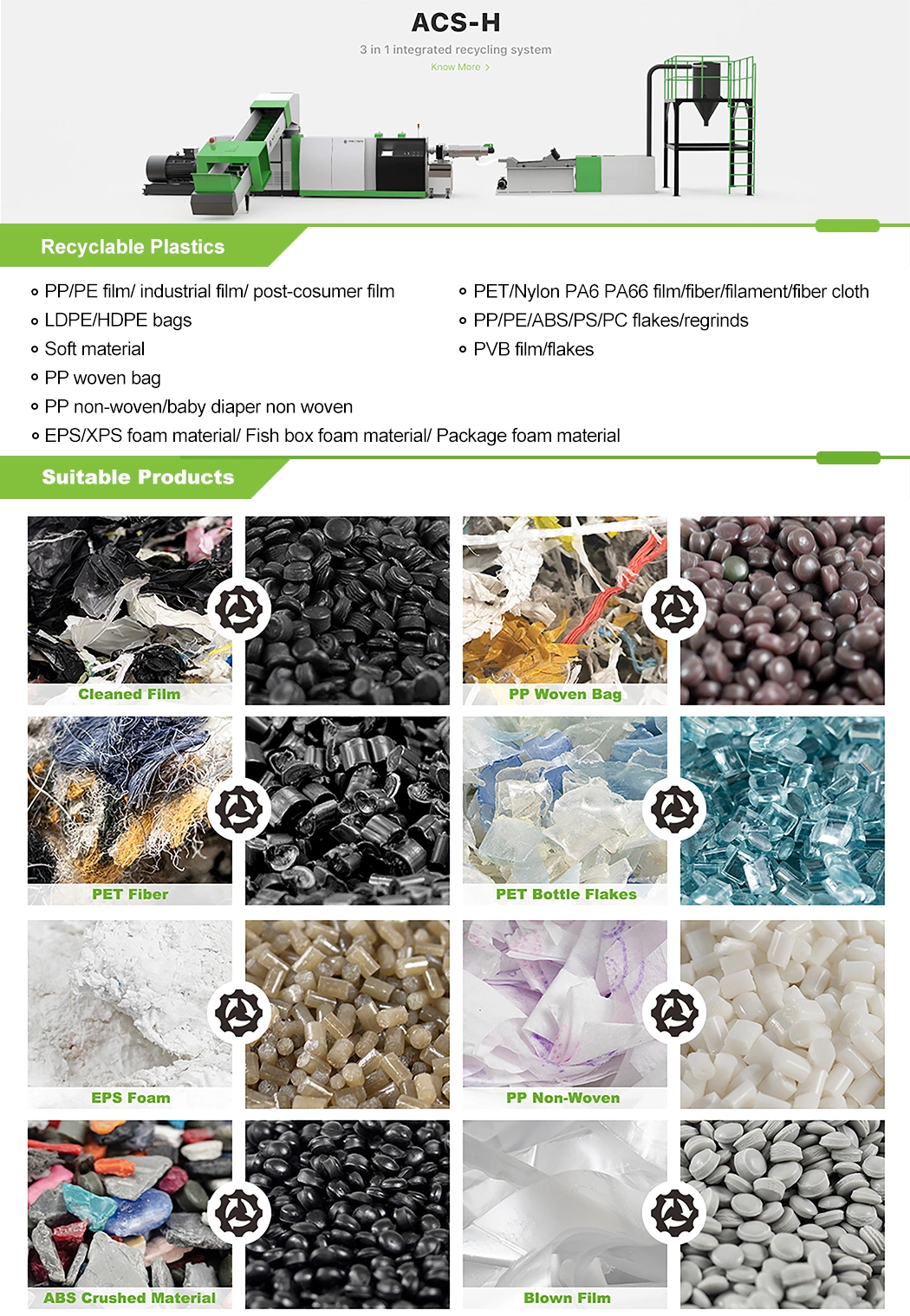

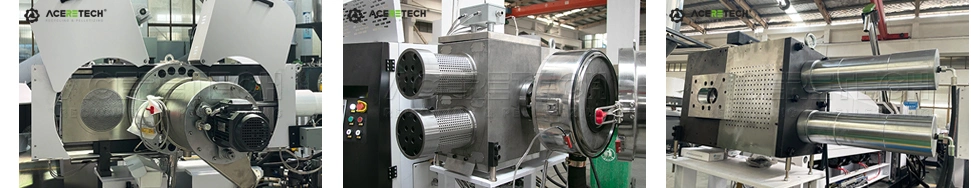

>> Multiple selection of smart feeding method: Plastic scraps can choose belt conveyor; Rolls' scraps can choose roll hauling off device;Feeding speed is automatically.>>> Strong crushing and compacting unit:Rotatory blades of compactor will cut up incoming scraps;Frictional heating will dry and compacts the materials;Feed from the compactor directly into the extruder.Sliding gate make it can handle both film and rigid scraps./p>>> Specialized single screw extruder: Equipped with high torque gearbox with integrated design; 34D to 36D processing section to gently melt the plastics;Bi-metal Screws and barrelsensure 2 times use life than usual.>>> Double-zone vacuum degassing system:Double-zone degassing can remove the volatiles efficiency;Equipped with vacuum tank, which store the impurities, small molecules or oil stains from the exhaust./p>>> Plate type double station filter: Cost - effective,Easy to operate;>>> Piston type large area filter:Suitable for heavy contaminated materialSuitable for large capacity recycling machine;>>> SCF type Self-clean filterNo need to change the mesh screen;Automatically discharge the impurities;Can realize 60mesh, 80mesh 100mesh and 120mesh./p>>> For different materials and different usage scenarios, we can provide you different pelletizing systems. Water-ring pelletizing system: Standard granulating method in ACS-H system; Self-adjusting pelletizing head ;RPM of rotatory blades is automatic./p>>> Under-water pelletizing system:Suitable for big capacity, automatically,Applicable to a wider range of materials./p>>> Water-strands pelletizing system:Cost-effective;Suitable for the material which MFI is higher than 8./p>>> Vibration: Sieve is made of Stainless steel ; Dewatering granules and selecting size.Centrifugal dryer:Horizontal-type which is lower energy consumption;Blower on the dryer to remove the moisture further;Equipped with sound-proofing cover to reduce noise.Product silo:All pipes and silos wrapped with sound -proofing cotton;Optional Capacity online monitoring & Quantitative weighing./p>>> Intelligence Start: One button only.>>> Intelligence Stop: One button only.>>> Emergency Stop: One button only.Remote monitoring and information transmission./p>

Informação básica.

| Modelo NÃO. | ACS-H |

| Parafuso | Parafuso Único |

| Inversor | Inversor |

| Aquecedor Eletromagnético | Aquecedor de cerâmica ou aquecedor infravermelho distante |

| Automação | Automático |

| Informatizado | Informatizado |

| Personalizado | Personalizado |

| Certificação | Marcação, ISO9001:2008, TUV |

| Doença | Novo |

| Localização da Fábrica | 2 horas de carro de Xangai |

| Serviço pós-venda | Peças sobressalentes gratuitas |

| Manua de amostra/serviço | Disponível |

| Ao controle | Controle CLP |

| Tipo de Negócio | Fabricante |

| Material | Ferro |

| Vantagem | Motor de marca famosa |

| Produto final | Pelotas/Grânulos |

| Compactando o tamanho da sala | 300-1400 litros |

| Aplicativo | Filme, Filamento, Ráfia, Espuma |

| Tensão | 380V 50Hz ou personalizado |

| Tipo de máquina | Máquina de reciclagem |

Você pode gostar

Enviar consulta

Envie agora